How dooes SAP PP module help my production planning process?

An efficient production planning leads to products with high quality and high margins. SAP Production processes can be quite complex and SAP PP Production Planning enables you to plan and simulate these. A well managed PP implementation can lead to very good forecasts across the board. Our consultants can work with your teams to achieve these goals

Having accurate master data is critical to long-term success of the production planning process. Vibhathi consultants understand the critical nature of this data and will work with you to ensure that it is curated properly. While it is a non-trivial exercise, master data management of key elements is vital to the long-term ability of the organization to produce good efficiently

The function of Demand Management is to estimate requirement quantities and delivery dates for finished products and important assemblies. Demand Management uses PIR (planned independent requirements) and customer requirements.

MRP determines any shortages and creates the appropriate procurement elements. It does net requirement calculation and generate planned orders for in-house produced materials and purchase requisition for raw materials. Our consultants can help ensure that production is never interrupted due to missing inventory

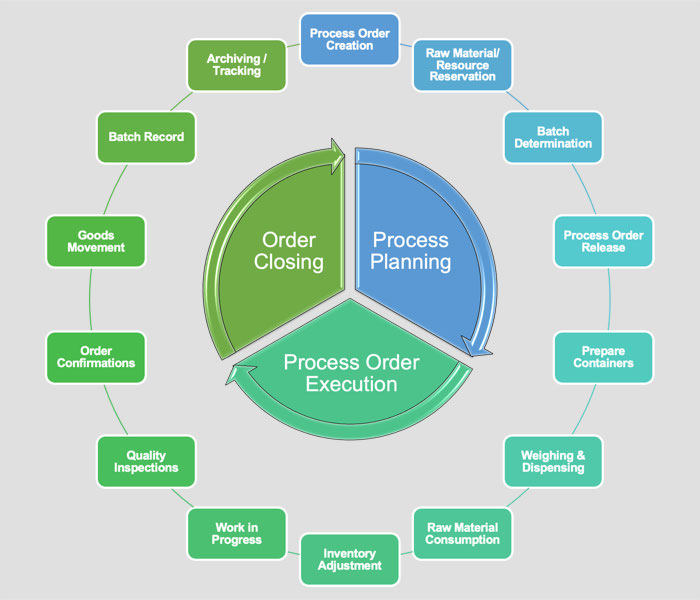

Production planning is generally done from budgeted sales plan. Planning is based on the Sales plan to meet the sales requirements as per the production cycle times. Demand for the Product is entered through demand management in the form of planned independent requirement (PIR). This data from demand management becomes the input to Material requirement planning (MRP). As MRP works with infinite capacities, capacity leveling must be done in order to avoid any capacity bottlenecks. Our functional consultants are available to support your needs in this process.

Planned orders are converted to Production orders at the end of the planning process, and are scheduled as per the production timings using master data such as routings. Production Orders are released after material availability checks. Production is carried out based on the activities maintained in the Routing where the master data like Work Center is mentioned against each operation in the Routing. Once the production is completed, the Confirmations of orders are executed, and goods movement for material consumptions & goods receipt are posted against the Order. Hence, the Order gets the Delivered (DLV) status, and the material is received into desired storage location. This is where the rubber meets the road and often users need clarifications and help from the functional support team

© 2021 - All Rights Reserved - Vibhathi Labs Inc.